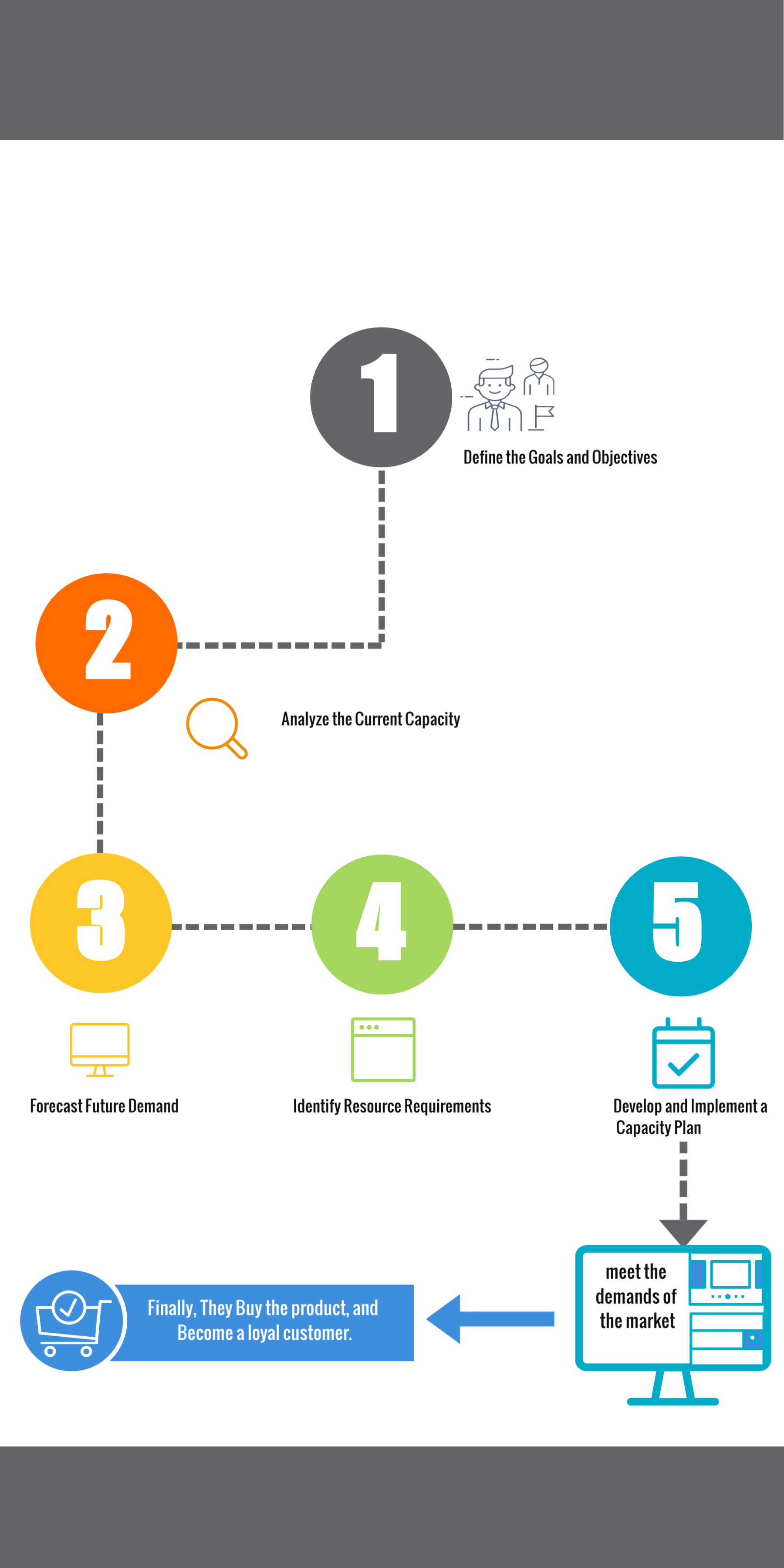

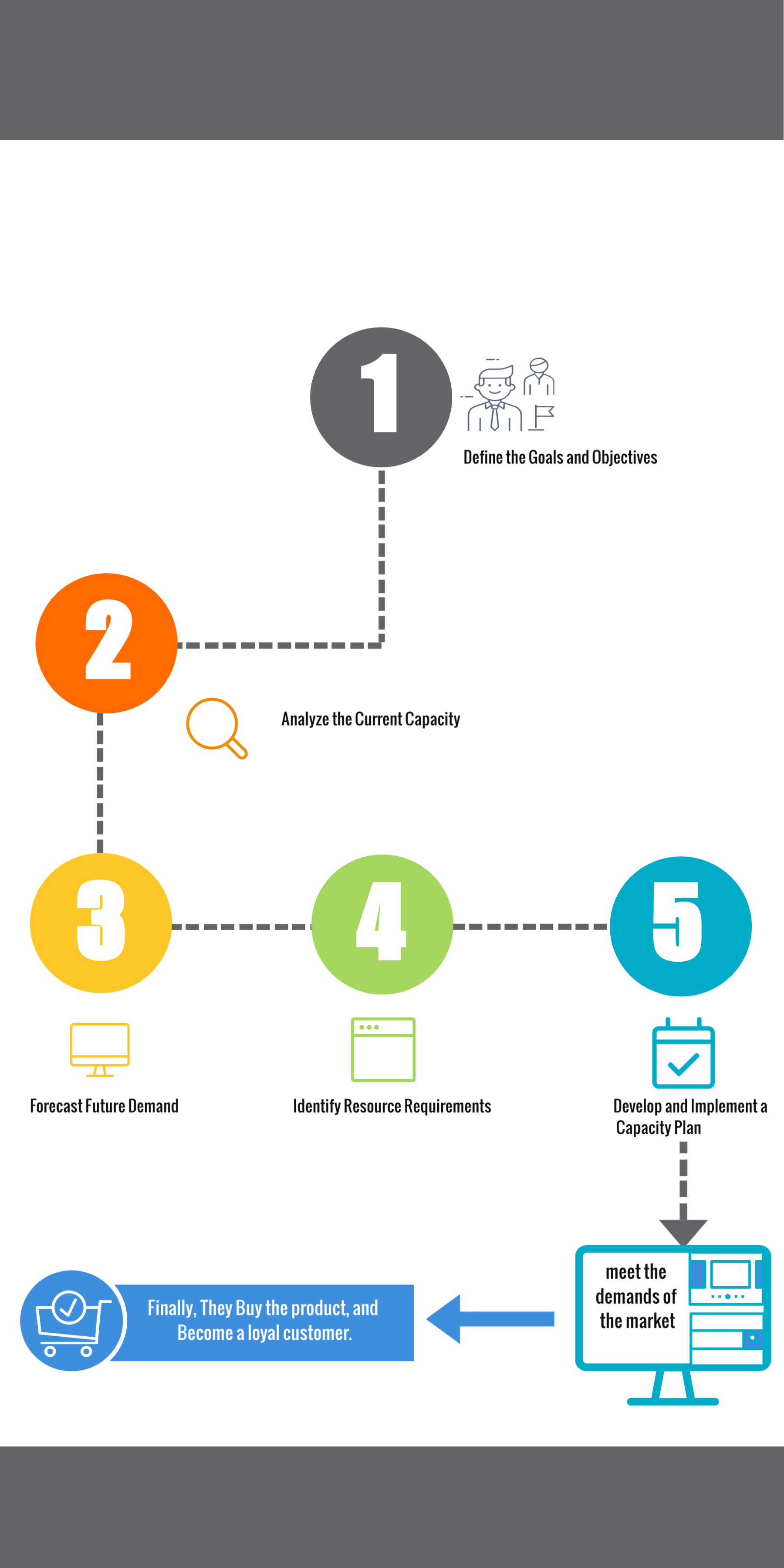

Step 1: Define the Goals and Objectives

The first step in capacity planning is to define the goals and objectives of the organization. This includes understanding the products and services offered, target market, and sales projections. For example, if you are a manufacturer of computers, your goal may be to increase production capacity by 20% over the next year to meet the expected demand.

Step 2: Analyze the Current Capacity

Once the goals and objectives have been defined, the next step is to analyze the current capacity of the organization. This includes evaluating the existing resources, including machinery, staff, and infrastructure. By understanding the current capacity, you can determine the gaps and identify the resources needed to achieve the goals. For example, if you are a restaurant owner, you may need to evaluate your seating capacity, kitchen equipment, and staff availability to determine the improvements needed to meet the demand.

Step 3: Forecast Future Demand

The third step is to forecast future demand based on historical data, market trends, and customer feedback. This helps to determine the expected levels of production or service requirements. For example, if you are a retailer, you may want to forecast the demand for a specific product during the holiday season to ensure that you have enough inventory available.

Step 4: Identify Resource Requirements

After forecasting future demand, the next step is to identify the resource requirements necessary to meet the demand. This includes determining the additional machinery, staff, and infrastructure necessary. For example, if you are a manufacturer of clothing, you may need to purchase new sewing machines and hire additional workers to meet the expected demand.